Sodium alginate & propylene glycol alginate uses in bakery

Sodium alginate and Propylene Glycol Alginate (PGA) used as quality improvers for cakes, bread, biscuits

The quality of baked foods such as biscuits, bread, and cakes has a lot to do with the quality of flour. If the gluten content of flour is too low, it will not be fermented well and not easy to swell when used in the production of bread, if it is used in the production of biscuits, its breakage rate increases, when used in the production of cakes, due to poor toughness, it is difficult to release the mold after baking and is easy to break.

The dough mixed with high-gluten flour is fermented normally, and there is obvious swelling after being baked in the oven. As the baking time increases, the gluten solidifies, the toughness increases, and the internal pressure of the dough increases, so that the bread gets a fluffy, uniform, and resilient internal structure. If the gluten of the flour is too weak, the gluten tissue cannot withstand a certain pressure and the small pores will burst into large pores, making the internal structure of the bread uneven and large cavities appearing, which will seriously lead to collapse.

Improve texture:

Sodium alginate is added, in which part of the anionic gene and the amino group in the gluten protein interact electrostatically to form a gluten protein hydrocolloid complex, which improves the gluten protein network structure, thereby improving the dough's kneading resistance and mechanical stirring force, and making the dough formation time , Stability time and farinity index are improved. With the increasing amount of sodium alginate added, the water absorption rate of the dough gradually increases. This may be due to the hydrophilic gene contained in sodium alginate, which binds a large number of water molecules through hydrogen bonds, making The water absorption rate of the dough is improved, and sodium alginate has good cohesiveness after absorbing water and swelling, which strengthens the combination degree of starch and protein in wheat flour, strengthens the network structure of gluten, and improves the viscoelasticity and plasticity of dough.

Enhanced water holding capacity:

Adding sodium alginate and propylene glycol alginate (PGA) can delay the increase of bread hardness and chewiness. The main reason is: as a hydrophilic colloid, when added to bread dough, it can increase the water absorption rate of bread dough and increase the water holding capacity of bread, make bread moist and soft, make more water molecules in bread exist in the form of stable bound water, which can better reduce the water activity of bread; and interact with starch molecules to form stable complexes, delaying the aging of starch.

Benefits and advantages:

Add volume, maintain shape

Enhance anti-aging ability and reduce slag

Enhance water holding capacity, soft and moist taste

Extend product shelf life

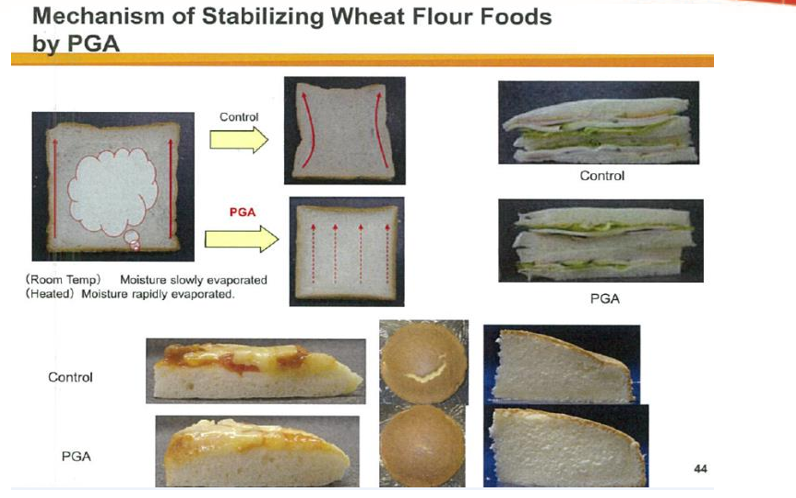

Prevents wrinkling and bending when microwaved

Prevent moisture from getting wet when filling

Dosage:

According to the specific effect achieved by the application of the product and the indicators required by the customer, provide the corresponding suitable specification monomer, or adjust the formula required for the compound product:

sodium alginate: Viscosity 500-600 mpa.s, the recommended addition amount is 0.1%-1%.

propylene glycol alginate (PGA): Viscosity 300-400 mpa.s, degree of esterification >85%, recommended addition amount 0.1%-0.5%.

compound product: as per customer request.