"Wear" seaweed fiber on the body

At the just-concluded Provincial Science and Technology Awards Conference, Qingdao University's "Seaweed Fiber Industrialization Complete Technology and Equipment" project won the first prize of the Provincial Technology Invention Award. This technology is a major breakthrough in the field of new materials in our city, and it is also a precious gift of rich ocean resources to the people here.

Seaweed fiber underwear

Seaweed fiber is called "the third fiber" by the industry. There are two main sources of traditional textile fibers, one is synthetic fibers based on petrochemical industry, the other is natural fibers (cotton, hemp, wool, silk, etc.) and terrestrial bio-based recycled fibers (mainly wood and bamboo as raw materials) . The project of Qingdao University asks for resources from the ocean and develops a third source of fiber, which can alleviate the contradiction between land and oil shortages, and at the same time rely on the excellent performance of marine bio-based fibers that are different from traditional fibers, which will bring an upgrade to the traditional textile industry to have a revolutionary impact.

It is understood that over the decades since the development of seaweed fiber preparation technology, the products of many professional manufacturers in the world can only be used as medical dressings due to their low strength, low production capacity, and failure to solve the dissolution and degradation phenomena in salt solutions and alkaline detergents. Seaweed fiber failed to achieve large-scale production in the field of clothing and textiles. After more than ten years of continuous research and development, Qingdao University has overcome a series of key technical problems in the industrial production of seaweed fiber, and realized the automatic large-scale production of seaweed fiber for textile and clothing with sodium alginate for the first time in the world.

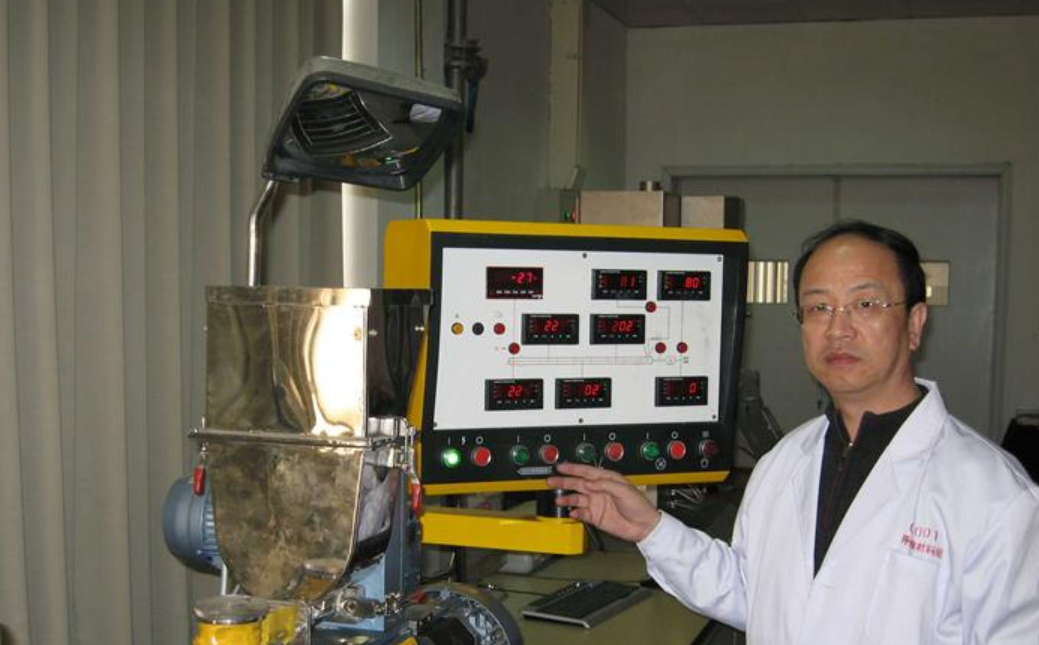

Xia Yanzhi, the first person to complete the seaweed fiber

According to Xia Yanzhi, director of Qingda Ocean Fiber New Materials Research Institute and the person who completed the project, his R&D team independently designed and developed a complete set of technology and equipment for seaweed fiber and special raw materials. The production efficiency of different sections of the production line is higher than that of the original small-scale production process. 5-20 times, the strength of the produced fiber has increased by more than 50%. The developed salt water-resistant and detergent-resistant seaweed fiber does not swell or dissolve after continuous soaking for 24 hours, and can be routinely washed. Relying on these patented technologies, the world's first 800-ton/year seaweed fiber automatic flexible production line has been built, and several 100-ton ordinary seaweed fiber production lines have been promoted and constructed, and three series of seaweed fibers for textile and clothing, medical and health care have been developed. A total of more than 20 products. At present, a new type of seaweed fiber production line with an annual capacity of 5,000 tons is under construction, which can produce three series of seaweed fibers for textile and clothing, medical and health care.