Sodium Alginate Fiber Grade

As a new type of biodegradable regenerated fiber, seaweed fiber is a fiber made of alginic acid isolated from seaweed, it features good biocompatibility, degradable absorption. Seaweed fibers have received extensive attention in the textile and medical- 9005-38-3

- C₆H₇NaO₆

- white powder

- 39131000

- 25kg/paper kraft bag

- Jiejing

Sodium alginate is a natural polymer material extracted from brown algae. It can be used as a raw material for wet spinning to prepare calcium alginate fibers. Sodium alginate and calcium alginate fibers are widely used in the textile and medical industry. As a professional fiber grade sodium alginate manufacturer and global supplier, Shandong Jiejing Group Corporation has been specialized in manufacturing and exporting sodium alginate for 56 years. Please be rest assured to buy sodium alginate from Shandong Jiejing. Any questions or inquiry feel free to contact us by email jiejinggroup@gmail.com, you will get response in one working day.

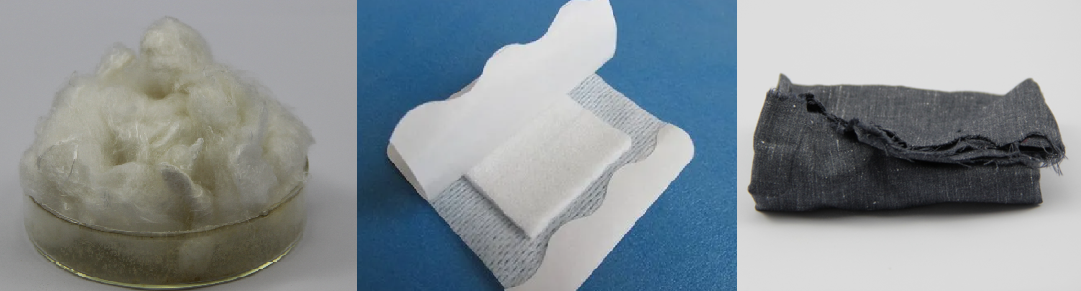

Production of seaweed fiber

1.Preparation of raw materials

At present, among the raw materials that can be used to produce seaweed fiber, the most commonly used is soluble sodium salt of alginic acid powder, namely sodium alginate.

Its production process: first treat seaweed with dilute acid to convert insoluble alginate into alginic acid, then add alkali to heat and extract to form soluble sodium salt to dissolve out, after filtration, add calcium salt to form calcium alginate precipitate, the precipitate is acidified. It is converted into insoluble alginic acid by liquid treatment, and converted into sodium salt by adding alkali after dehydration, and get sodium alginate powder after drying.

2.Preparation of seaweed fiber

Seaweed fibers are usually prepared by wet spinning, that is, soluble alginate (usually sodium alginate) is dissolved in water to form a viscous solution, which is then extruded through spinneret holes into a coagulation bath containing divalent metal cations (except Mg2+) to form solid insoluble alginate fiber filaments.

3. Characteristics of seaweed fiber

3.1 High hygroscopicity

It can absorb a large amount of wound exudate, prolong the time for changing bandages, reduce the number of changes and nursing time, and reduce nursing costs.

3.2 Ease of removal

Alginate fibers swell to form a soft gel upon contact with exudate. High-M alginate fibers can be removed by rinsing with warm saline solution; high-G alginate bandages are less bulky and can be removed as a whole, which has a protective effect on the delicate tissue of new wounds and prevents secondary trauma to the wound when the gauze is taken out .

3.3 High oxygen permeability

After moisture absorption, a hydrophilic gel is formed, and the "free water" combined with the hydrophilic group becomes the channel for oxygen transmission. The oxygen enters the wound tissue from the external environment through the process of adsorption-diffusion-desorption; while the high G segment of the fiber is the connection point of the macromolecular skeleton of the fiber, and the hard part of the hydrogel (micropores through which oxygen can pass) avoid the hypoxic condition of the wound and promote wound healing.

3.4 Gel blocking property

When the alginate bandage is in contact with the exudate, it swells, and a large amount of exudate remains in the gel fiber, and the swelling of the single fiber will reduce the pores between the fibers and stop the spread of the fluid, because the "gel" of the alginate bandage The special feature of "blocking" can make the wound exudate spread, and the corresponding maceration effect is reduced.

3.5 Biodegradability and compatibility

Alginate fiber is a biodegradable fiber, which solves the problem of environmental pollution. Its biocompatibility can avoid secondary stitches removal during operation and reduce the pain of patients.

3.6 Adsorption of metal ions

Seaweed fiber can absorb a large amount of metal ions to form conductive chains, which can improve the aggregation performance of macromolecular chains, and is suitable for making protective textiles.

The development prospect of seaweed fiber

In recent years, Qingdao University has successfully prepared high-strength seaweed fibers with a strength of 46.75cN/tex through wet spinning method through research on the structure and properties of seaweed fibers and optimization of process parameters.

Seaweed fiber can be said to be the most perfect clothing material found now, and it may be seen everywhere in the near future. On the street, people wearing seaweed clothes will not sweat like rain in midsummer; mothers-to-be wearing seaweed clothes don't have to worry about radiation hazards to unborn babies; little girls play with Barbie dolls in seaweed clothes. At home, the bed is covered with seaweed sheets , seaweed quilt covers, and seaweed curtains hung on the windows. In the operating room, the doctor took the gauze made of seaweed fibers and used surgical sutures made of seaweed fibers to complete the operation. At the scene of the fire, firefighters wore seaweed protective clothing, which was safer and more comfortable. Maybe you and I are also wearing these clothes made of seaweed fibers.

sodium alginate fiber.png"/>

sodium alginate fiber.png"/>

sodium alginate for fiber specification

| Appearance | white powder |

| Viscosity | medium viscosity |

| Particle size | 80mesh |

| Content | 90.8%-106.0% |

| Loss on drying | ≤15% |

| Water insoluble matter | ≤2% |

| Ash | 18.0-27.0% |

| PH | 6-8 |

| Asernic | ≤3mg/kg |

| Lead | ≤5mg/kg |

| Mercury | ≤1mg/kg |

| Cadmium | ≤1mg/kg |

| Total plate count | <5000cfu/g |

| Yeast and moulds | <500cfu/g |

| Escherichia Coli | NEGATIVE IN 5G |

| Salmonella | NEGATIVE IN 10G |

Package: 25kg paper kraft bag

FAQ

1. What kinds of certificates can supply?

Shandong Jiejing Group is an ISO2008 9001, ISO14001 certified company. We can supply ISO22000 (HACCP), KOSHER, HALAL, BRC Certificates.

2. Is Shandong Jiejing Group Corporation a manufacturer or a trading company?

Shandong Jiejing Group Corporation is not only a manufacturer, but also a pioneer in the industry since 1968. Our manufacturing site covers 133,200 square meters. We devote ourselves to leading the sustainable development of alginate industry. We would like to cooperate with all distributors, traders, wholesalers, retailers and end-users.

3. What is the Min Order Quantity of fiber grade sodium alginate?

Generally our MOQ of fiber grade sodium alginate is 500kg. But it depends, if your quantity is less, we also can accept it.

4. Can you supply fiber grade sodium alginate sample for test before official order?

For sure, 200g free fiber grade sodium alginate sample is available for your analysis. You also can buy more sample according to your actual situation.

5. What is the price of fiber grade sodium alginate?

As the leading fiber grade sodium alginate manufacturer and exporter in China, our sodium alginate price is very competitive. And you can get discount based on order quantity.

6. What's your packing size of textile grade sodium alginate?

Our fiber grade sodium alginate packing is 25kg/paper kraft bag, or customized. Your own brand or logo or buyer information can be sticked onto bags. Each pallet is 1000kg.

7. What kinds of transportation can you offer?

We can offer by sea, by air, by courier, by train, any transportation you can do.

8. What kinds of payment terms can you accept?

We can accpet TT, LC, CAD, DP etc.

9. What's the lead time?

Generally we can make shipment in 15 working days after order confirmation. If quantity is for LCL shipment, generally we can ship promptly.

Related product

© Copyright - 2023 | Shandong Jiejing Group Corporation All Right Reserved.

Leave Comment